400 099 7576

400 099 7576Indentation is intuitively displayed,and readings are automatically measured

Test force closed-loop control system

Automatically generate curves and reports to meet the needs of experimenters

Large digital display screen,supports hardness scale conversion

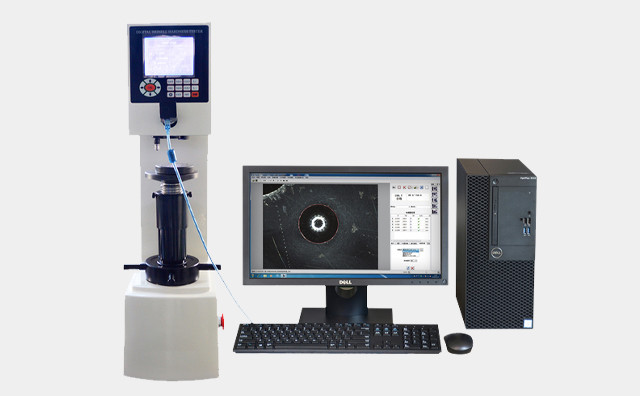

CCD image automatic measurement system is suitable for digital display Brinell hardness tester.

It is used for hardness determination of materials such as cast iron, steel, non-ferrous metals and soft alloys, and is also suitable for determination of hardness of some non-metallic materials such as hard plastics and bakelite.

The CCD image automatic measurement system is a combination of computer microcomputer automatic measurement software and hardness tester, so that the entire test process can be completed through simple operation of keyboard and mouse. It is easy to operate, has high measurement accuracy, minimizes human errors and avoids visual fatigue of operators, and can meet various hardness test requirements. The system uses a CCD camera, which can directly observe and measure indentations on the display. It can quickly operate the setting of test conditions and display results, statistical calculation, conversion, display curves, judge whether it is qualified, etc., and save the data results into WORD or EXCEL files.

1. Basic functions: Contains all functions of image processing and measurement systems, including image capture, calibration, image processing, geometric measurement, document annotation, album management, and fixed-multiple printing;

2. Automatic measurement: Automatically capture indentation and measure indentation diameter and calculate the corresponding Brinell hardness value;

3. Hardness value conversion: The system can convert the measured Brinell hardness value HB into other hardness values such as HV, HR, etc.;

4. Data statistics: The system automatically calculates the average value, variance and other statistical values of the measured hardness;

5. Exceeding standard alarm: Automatically indicate abnormal values, and automatically alarm when the hardness exceeds the specified value;

6. Test report: Automatically generate WORD or EXCEL format report, and the report template can be provided by the user.

7. Easy to use: click the interface button to complete all the work automatically; if you need to measure or modify the results manually, just drag the mouse;

8. Strong noise resistance: advanced and reliable image recognition technology can handle indentation recognition on complex sample surfaces, and two automatic measurement modes can handle extreme situations;

9. utomatic calibration: The system has provided a calibration function, which is convenient for indentation size measurement and can be calibrated at any time. If equipped with a calibration grid, the system can automatically perform full-image calibration on the intersection of the calibration grid to eliminate the measurement error caused by lens distortion.

XHB-3000/CCD Digital Display Brinell Image Automatic Measurement Hardness Tester

Selection Guide:

|

Name |

Quantity |

Remark |

|

computer |

1pc |

I3 processor,4G storage, 500G hard disk, 19inch LCD |

|

Inkjet Printers |

1pc |

|

|

CCD Camera |

1pc |

1.3 million pixels |

|

USB Dongle |

1pc |

|

|

Mearsurement Software |

1pc |

|

PDF

PDF

下载

下载

The customer's agreement is truly good! Whether it's products or services, the genuine feedback from customers is the source of our continuous improvement. Customer recognition is our unparalleled glory.

TOP