400 099 7576

400 099 7576A large vertical grinding and polishing machine that efficiently processes large quantities of samples……

Large capacity,suitable for large areas,large batches,and high hardness samples

Durable structural design,capable of carrying day after day uninterrupted and efficient work

Powerful power maximizes material removal

Electronic force measurement system and automated quantitative grinding make it easy to monitor the height of removed materials

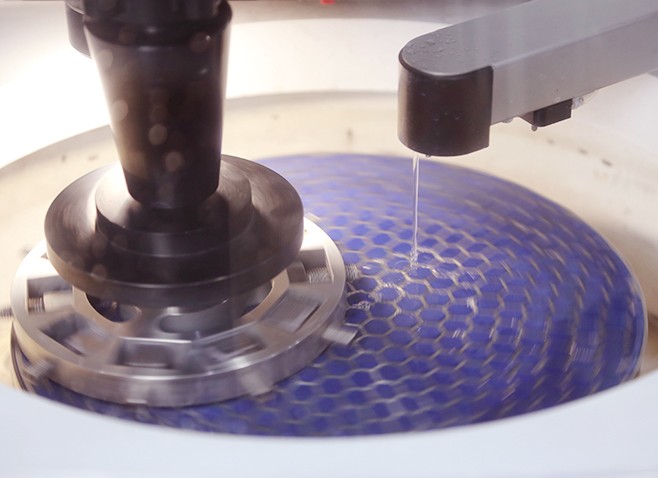

Automatic liquid addition device

Having method databases and custom databases

Reliable security performance

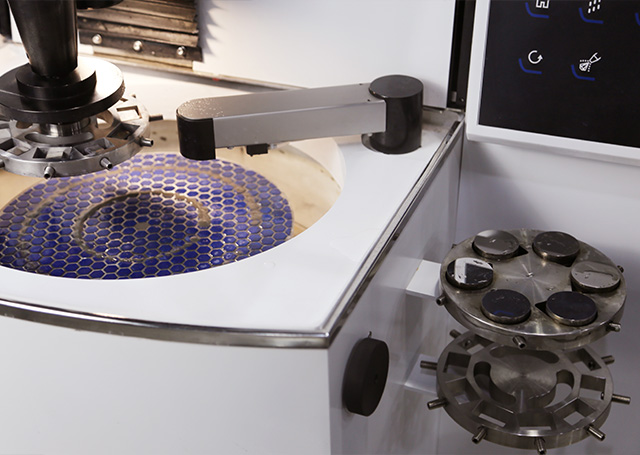

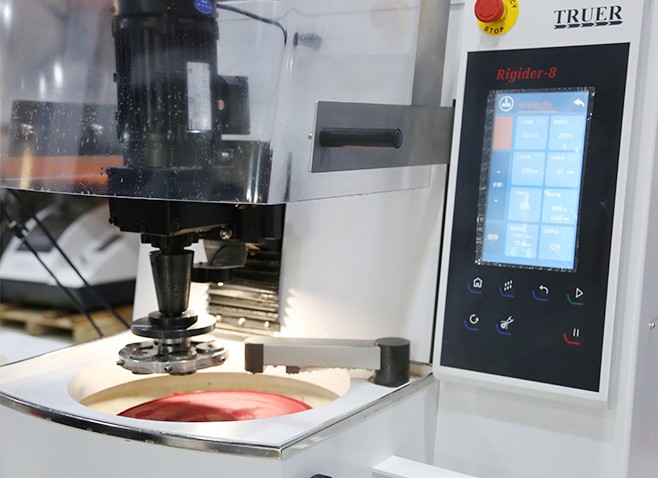

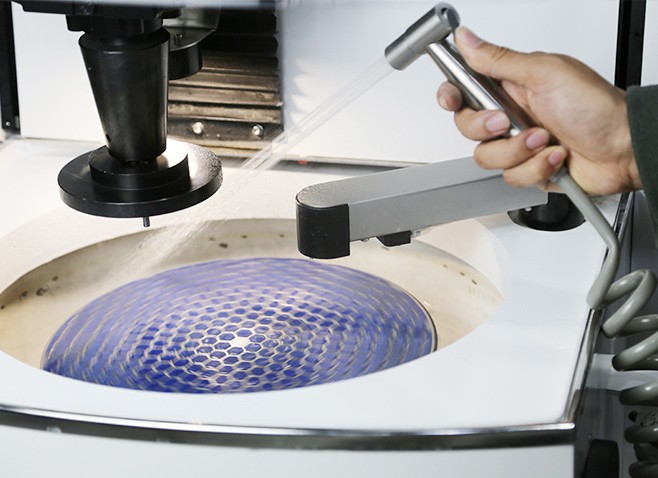

Rigider-8 is a large capacity automatic vertical grinding and polishing machine, particularly suitable for workplaces that require quality control testing of ultra large or large batches of samples, as well as for high hardness/large-area samples that require grinding and polishing. Compared with other similar machines, it can hold a larger number of samples and samples of different sizes, shorten the overall sample preparation time, and thus improve efficiency.

.jpg)

- The Rigider-8 automatic vertical grinding and polishing machine is a powerful high-capacity machine with a high-power motor installed in a sturdy welding frame. The entire machine is designed specifically for vibration free sample preparation. The machine can quickly and easily process any sample and is suitable for any working environment. Year after year, it meets the daily requirements for preparing large quantities and heavy-duty, high hardness metallographic specimens.

.jpg)

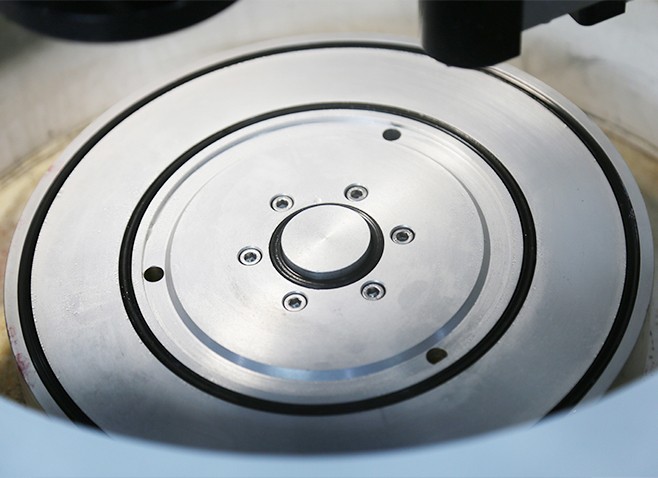

- Rigider-8 is currently one of the most efficient sample preparation machines in the market. Compared with other similar machines, it can hold a larger number of samples and samples of different sizes, shorten the overall sample preparation time, and improve efficiency. The grinding head speed of Rigider-8 can reach up to 300rpm/min, the pressure can reach 700N, and the working disc size can reach up to 350mm. The combination of parameters and sturdy structure makes the sample preparation efficiency very outstanding.

- The use of Rigider-8 to prepare grinding discs and sample thrusters has the advantage of variable speed. The speed of preparing the grinding disc can be increased from 50rpm to 500rpm, with one step every 10rpm; The rotational speed of the sample thruster can be increased from 50rpm to 300rpm, also every 10rpm.

- When grinding, the sample material must be removed by high-speed rotation of the grinding disc. Therefore, the high speed of 500rpm here can ensure a short preparation time。

- During precision grinding and polishing, the variable rotational speed of the grinding disc and the variable rotational speed of the sample holder mean that lower rotational speeds can be used to prepare samples for sensitive materials, or higher rotational speeds can be used to prepare samples for hard wear-resistant materials in the shortest possible time。

- Explosion proof transparent window design: The work area adopts a safe and reliable explosion-proof transparent window design. The machine cannot be started until the safety cover is closed, and the safety cover can only be opened after it has stopped running.

- Emergency stop and electromagnetic lock device: The machine is also equipped with an emergency stop device, and all functions will immediately stop when the device is pressed. The installation of electromagnetic lock safety system on the equipment ensures safety during operation, as the cover cannot be opened.

Rigider-8 Vertical large capacity automatic grinding and polishing machine

Rigider-8 is a large capacity automatic vertical grinding and polishing machine, particularly suitable for workplaces that require quality control testing of ultra large or large batches of samples, as well as for high hardness/large-area samples that require grinding and polishing. Compared with other similar machines, it can hold a larger number of samples and samples of different sizes, shorten the overall sample preparation time, and thus improve efficiency.

|

Number |

Main parameter types |

data |

|

1 |

INPUT VOLTAGE |

AC220V 50Hz |

|

2 |

Work disk (grinding and throwing disk) |

diameter:300mm or 350mm rotational speed:50~500r/min, Adjustable, step by step10rpm |

|

3 |

Sample holder (grinding and polishing head) |

rotational speed:50~300r/min, Adjustable, step by step10rpm10rpm Rotation direction: clockwise/counterclockwise pressure:50~700N Maximum diameter:200mm |

|

4 |

Automatic liquid addition |

Up to 6 pumps, with 4 pumps as standard |

|

5 |

Sample preparation time |

0~999秒(extendable) |

|

6 |

Input power |

2.2KW |

|

7 |

water supply |

1~4bar Minimum water flow:10l/min |

|

8 |

air supply |

Compressed air pressure:0.65~0.7mpa |

|

9 |

External dimensions |

Width x Depth: 88.5 x 102CM Height:Protective cover closed:163CM Protective cover open:194CM |

|

10 |

net weight |

400 kg |

PDF

PDF

下载

下载

The customer's agreement is truly good! Whether it's products or services, the genuine feedback from customers is the source of our continuous improvement. Customer recognition is our unparalleled glory.

TOP