Electrolytic polishing machine

Preparation based on electrochemistry principle

High voltage and current

Suitable for welding metallographic samples

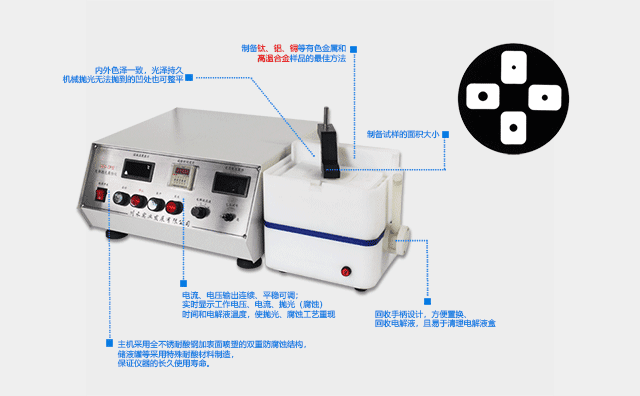

The electrolytic polishing and corrosion instrument is a metallographic sample preparation instrument that integrates electrolytic polishing and corrosion functions. It is suitable for use in laboratories such as factories, colleges and universities, and scientific research institutions. The instrument uses the electrochemistry principle to prepare metallographic samples. The metallographic samples prepared by electrolytic polishing and corrosion avoid the deformation layer caused by mechanical polishing, so their organization is real and without illusion. Therefore, it is the best method for preparing non-ferrous metals and high-temperature alloy samples such as titanium, aluminum, and copper. The instrument is designed with a higher working voltage and a larger working current, leaving a larger margin for the metallographic preparation of larger-sized samples, and is particularly suitable for the preparation of welding metallographic samples.

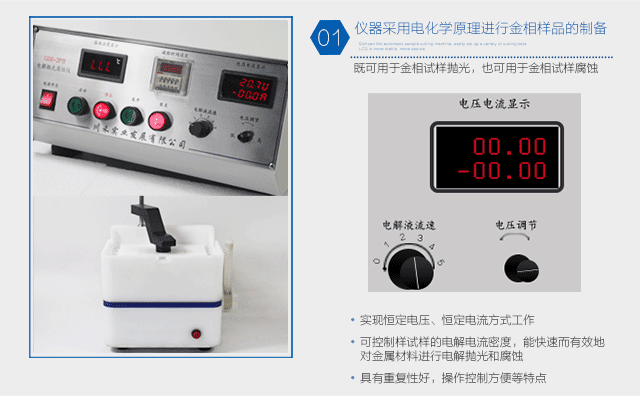

The instrument uses electrochemistry principles to prepare metallographic samples.

A metallographic sample preparation instrument that integrates electrolytic polishing and corrosion functions.

The best method for preparing non-ferrous metals and high-temperature alloy samples such as titanium, aluminum, and copper.

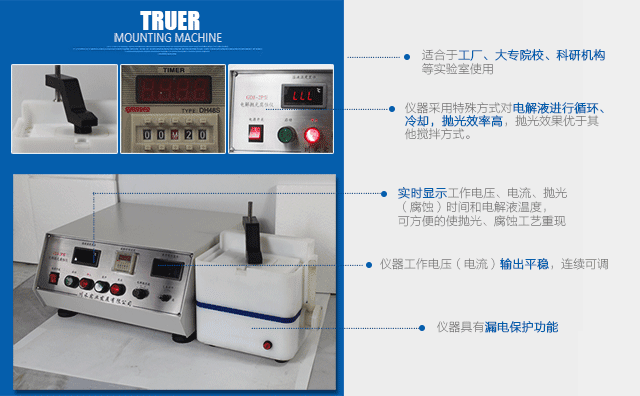

Long lifetime, stable and reliable performance.

Suitable for use in laboratories such as factories, colleges and universities, scientific research institutions, etc.

Real-time display of working voltage, current, polishing (corrosion) time and electrolyte temperature to enable polishing.

It helps to evaluate the metallographic structure and thermal processing technology of materials.

Electrolytic polishing corrosion preparation effectively avoids the deformation layer caused by mechanical polishing.

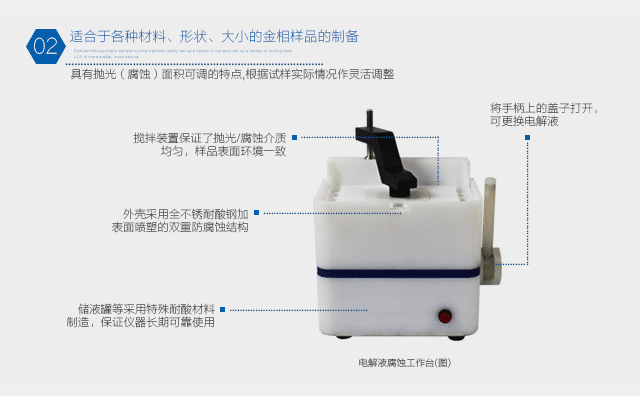

Suitable for the preparation of metallographic samples of various materials, shapes and sizes.

It has the characteristics of adjustable polishing (corrosion) area, which can be flexibly adjusted according to the actual situation of the sample.

GPJ-2P electrolytic polishing and corrosion tester achieves quality with details and builds a brand with integrity.

Suitable for use in laboratories such as factories, colleges and universities, and scientific research institutions.

After setting the time, place the sample to be processed on the small hole of the sample cup. The size of the small hole can be selected as needed. The sample height is 10∽30mm;

Place it on the workbench and place the anode on the sample.

Then press the "Pump On" button to try and see if the liquid can rise. Press the "Pump Off" button to turn it off if it rises,

Press the "Start" button to start working, and the time starts to count down. The work stops when the time is up.

GDJ-2P Electrolytic Polishing and Corrosion Tester

The electrolytic polishing and corrosion instrument is a metallographic sample preparation instrument that integrates electrolytic polishing and corrosion functions. It is suitable for use in laboratories such as factories, colleges and universities, and scientific research institutions. The instrument uses the electrochemistry principle to prepare metallographic samples.

The metallographic samples prepared by electrolytic polishing and corrosion avoid the deformation layer caused by mechanical polishing, so their organization is real and without illusion. Therefore, it is the best method for preparing non-ferrous metals and high-temperature alloy samples such as titanium, aluminum, and copper. The instrument is designed with a higher working voltage and a larger working current, leaving a larger margin for the metallographic preparation of larger-sized samples, and is particularly suitable for the preparation of welding metallographic samples.

|

No |

ltem |

Parameters |

|

1 |

Input voltage |

AC220V,10A(max) |

|

2 |

Electrolysis output |

DC0~60 V/0~25,continuous adjusted,number display |

|

3 |

Time display |

can be freely set about working time |

|

4 |

Electrolyte capacity |

300~1000ml; |

|

5 |

Electric box size |

450×420×230 |

|

6 |

Corrosion workbench |

270×230×320 |

|

5 |

Instrument weight |

10Kg |

PDF

PDF

下载

下载

客户说好才是真的好!无论产品还是服务,客户的真实反馈,是我们持续进步的源泉。客户的认可,是我们无尚的荣光。

TOP