400 099 7576

400 099 7576Easy to face all challenges

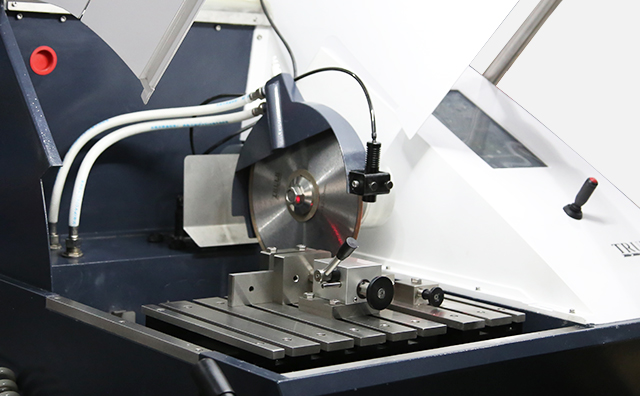

Efficient cutting and positioning

High-quality components

Thickened cast aluminum,rigid and stable

Large cutting room and cutting table

Uniform speed, pulse,batch,manual and other cutting modes

X,Y axis intelligent feed control

Real-time load display and intelligent protection function

High-quality components

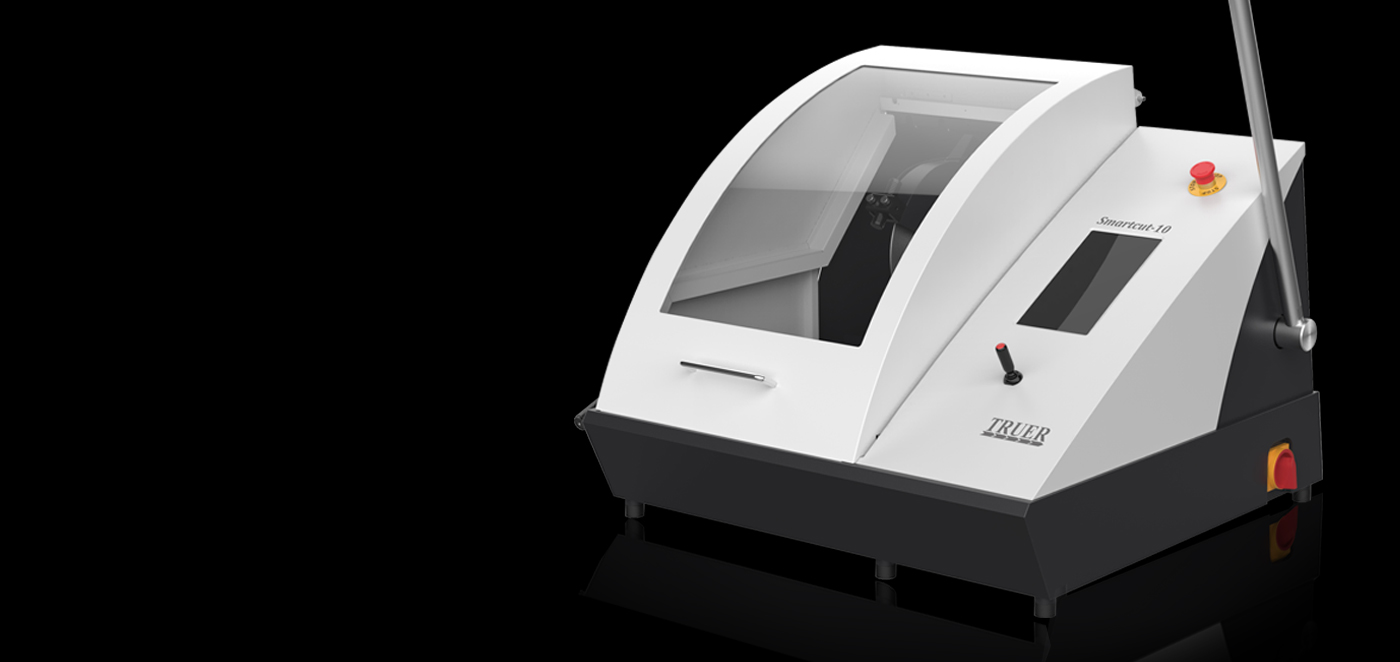

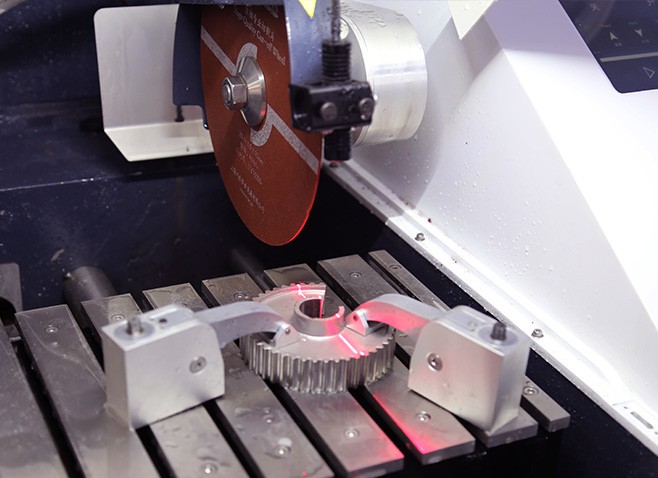

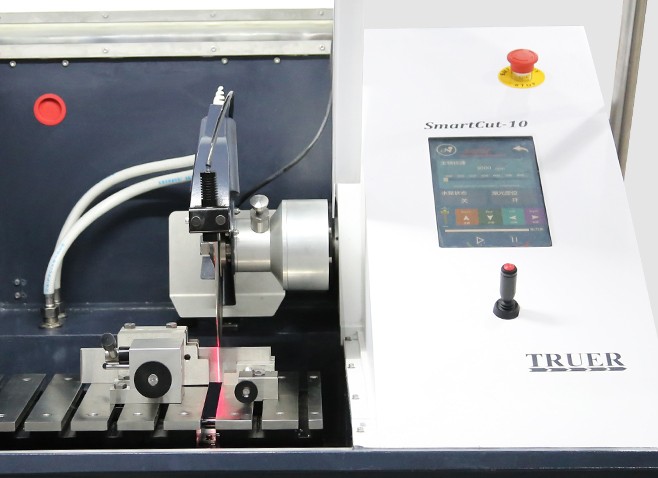

SmartCut-10/100 is a manual and automatic metallographic cutting machine that can precisely cut all kinds of workpieces. It consists of a machine body, an electric control box, a large-volume cutting chamber, a cooling system and other components. It has a variety of flexible cutting modes such as uniform speed, pulse, batch, and manual, which can quickly and efficiently clamp and cut various materials with minimal cutting deformation.

safe and reliable extra-large observation room;explosion-proof transparent window design.

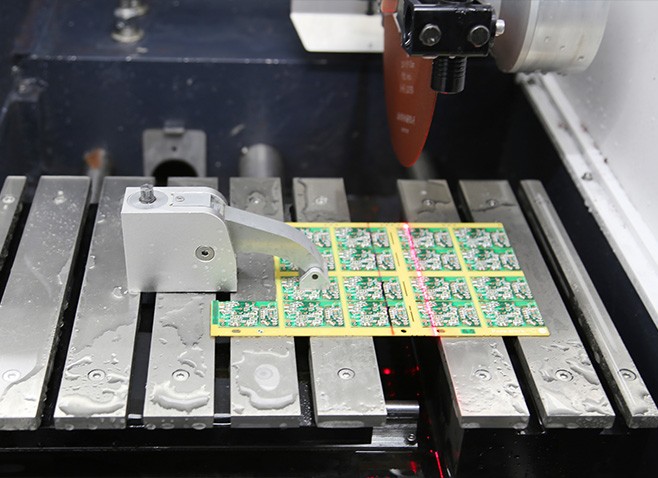

It has a large cutting table and cutting room. The cutting table size is 440 x 270mm, which can clamp and cut all types of work pieces including large and complex samples.It is no need to have rough cutting on another machine.

Removable baffle, can cut extra-long work pieces.

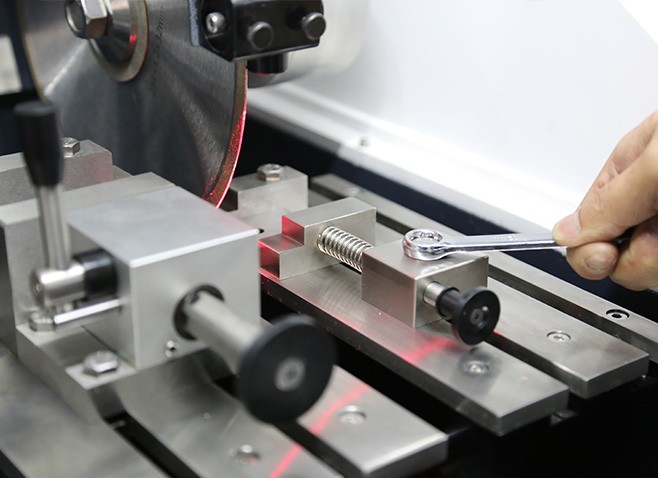

- Unique workbench design:he suspended workbench makes walking smoother and drainage smoother. The support rail design ensures stable support of the workbench. The stainless steel sleeve ensures that the transmission rod is not contaminated and hit. The integrated X-movement module can achieve precise tool setting and batch cutting. It is easy to clean and rust-free by using the stainless steel standard cutting workbench.

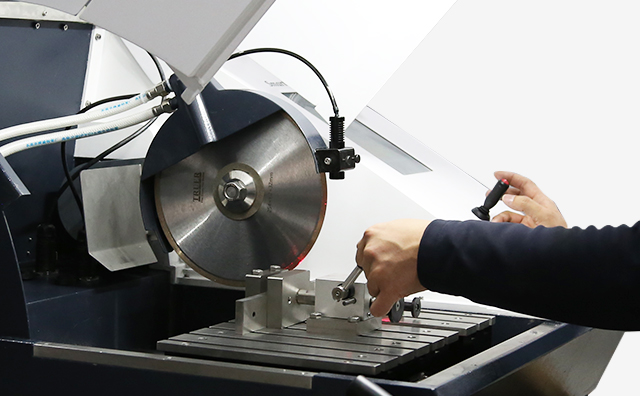

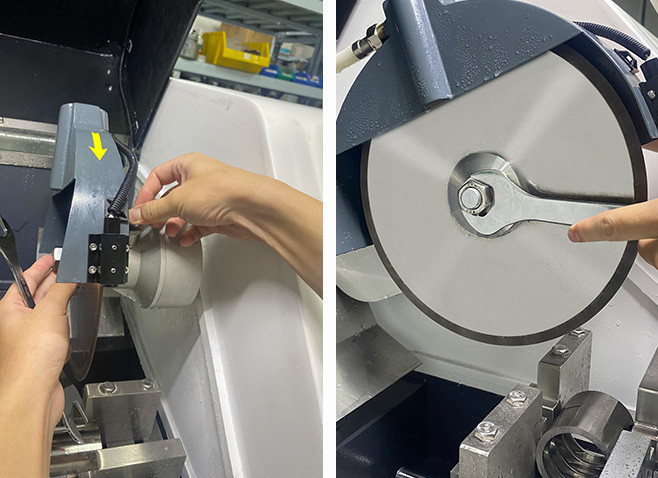

- A wide variety of fixtures:The suspended equipment is suitable for flexible clamping of various fixtures and supports the fixing of special-shaped samples. The matching fixtures are: fast push fixtures, elephant trunk fixtures, rotary fixtures, etc.

In SmartCut manual cutting mode, use the pull rod to manually perform "straight cutting" in the Z-axis direction or use the longitudinal movement handle to perform longitudinal cutting in the Y-axis direction.

The three cutting methods in the automatic cutting mode provide more abundant application scenarios, reflecting more powerful cutting capabilities and flexibility.

There are three automatic cutting modes

A.Uniform speed cutting:For materials with known cutting characteristics, you can directly set the workbench moving distance and ideal feed speed to complete the cutting task automatically.

B.Pulse cutting:It is mostly used for automatic cutting of special metal samples or samples with hard and brittle materials. Set the workbench travel distance and feed speed, as well as the feed and retreat amount required by the pulse to complete the cutting task automatically .

C.Batch cutting:It is suitable for the same regular work piece and is mostly used for non-hard samples. In addition to setting the workbench moving distance and feed speed, it is also necessary to determine the side shift amount and the number of cuts. After the first sample cutting action is completed, the workbench automatically returns to the starting position, the X side shift table feeds and then the next cutting is started.

.jpg)

- Rigid structure:adopts high strength thickened aluminum technology with safe stable design in explosion-proof transparent window to ensure the ability of hardness and anti-corrosion.

- Separated dry and wet bin:The main motor and electronic control components are placed in the dry compartment which can effectively extend the service life of electronic devices and ensure safety.

- Real-time load display and intelligent protection function:When the load exceeds the set safety value the workbench will stop feeding by the automatic detection motor power. The set feeding speed is restarted when the cutting disc speed returns to normal

- Double-protected safety lock:The mechanical and electronic double-protected safety lock prevents any misoperation of opening the cover during the cutting process. At the same time, a delayed unlocking function is designed to ensure that the cover can be opened only after the cutting blade stops rotating. The motor is equipped with a brake function to shorten the inertial operation time after shutdown.

.jpg)

The system matches the appropriate cutting disc from Truer according to the hardness of different materials.Automatically generates the matching spindle speed according to the model of the cutting disc.

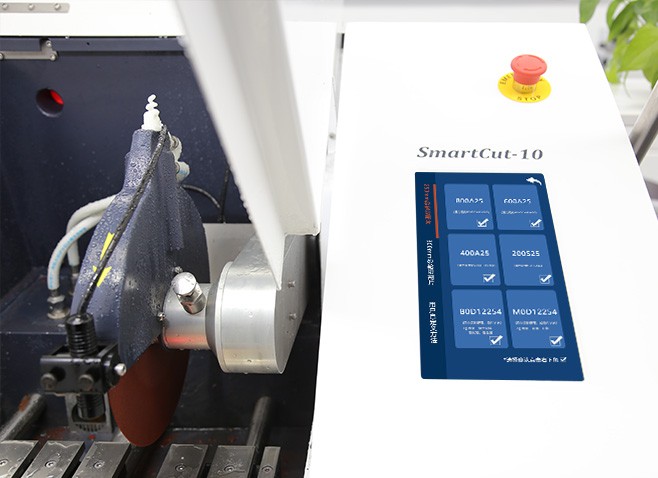

Users can customize multiple methods and call them at any time to ensure that consistent and reproducible slicing results can always be achieved.

SmartCut-10/100 is a manual-automatic cutting machine that can

precisely cut all kinds of work pieces. It can provide economical and

effective cutting modes in switching between automatic and manual

at will. It can set the cutting speed and cutting process. Users can

customize a variety of cutting methods and call them at any time

with a 10-inch touch screen, It is very suitable for cutting various

metal and non-metal work pieces

Demo

干湿仓分离

主电机置于干仓,通过转轴旋转带动位于湿仓的传动摆臂进行切割,最大限度的保护主电机。

440×270mm大容量切割台

灵活极易拆装的夹具

标配快速夹具,能实现精准定位,快速夹紧试样,操作方便简单。

极易上手的便捷性

明亮的照明

切割机罩内置铝制的高亮LED照明灯,能耗小,亮度高,防水防锈, LED灯管置于机盖上方,无论切割室打开还是关闭,它都能照亮整个切割室。

自动X移动平台

激光定位

快速激光定位装置,方便切割片定位模拟。

超凡大流量水路

方法库

便捷拆装切割片

10寸触控大屏+工作台移动手柄

冲洗水枪

便携式冲洗水枪,握感舒适,手握为旋钮式,水管为螺旋伸缩水管,可有效冲走切割后残留的污垢。

SmartCut-10/100手

SmartCut-10/100 is a manual-automatic metallographic cutting machine that can precisely cut all kinds of work pieces.

It consists of a machine body, an electric control box, a large-volume cutting chamber, a cooling system and other components. It has a variety of flexible cutting modes such as uniform speed, pulse, batch, and manual, which can quickly and efficiently clamp and cut various materials with minimal cutting deformation.

|

Parameters |

SmartCut-10 |

SmartCut-100 |

|

Input Voltage |

Single phase AC220V 50Hz |

Three-phase 380V 50Hz |

|

Input Power |

2.5KW |

3KW |

|

Spindle Rotation |

50~3000 rpm/min |

|

|

Cutting Surface(max.) |

95mm |

115mm |

|

Automatic cutting Moving Distance(max.) |

Y-axis stroke:180mm;X-axis stroke:50mm |

|

|

Matching Cutting DiscSize(diameter x thickness x centerhole) |

Φ250×1.5×32mm |

Φ300×2.0×32mm |

|

Workbench Size |

440×270mm |

|

|

Outer Size |

920×880×1020mm |

|

|

Water Tank Size & Capacity |

570×440×360mm;90L |

|

|

N.W. |

220KG |

230KG |

PDF

PDF

下载

下载

The customer's agreement is truly good! Whether it's products or services, the genuine feedback from customers is the source of our continuous improvement. Customer recognition is our unparalleled glory.

TOP