400 099 7576

400 099 7576A grinding and polishing machine that subverts usage habits……

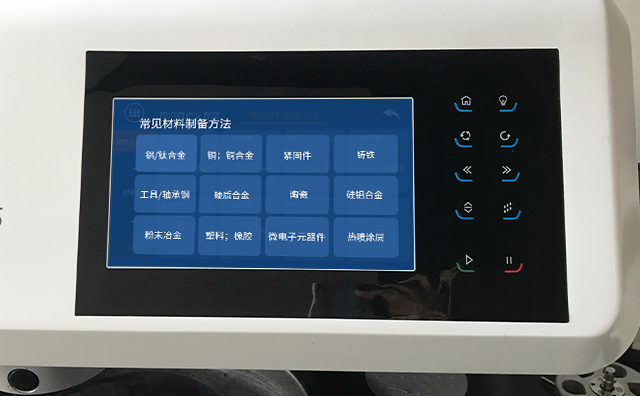

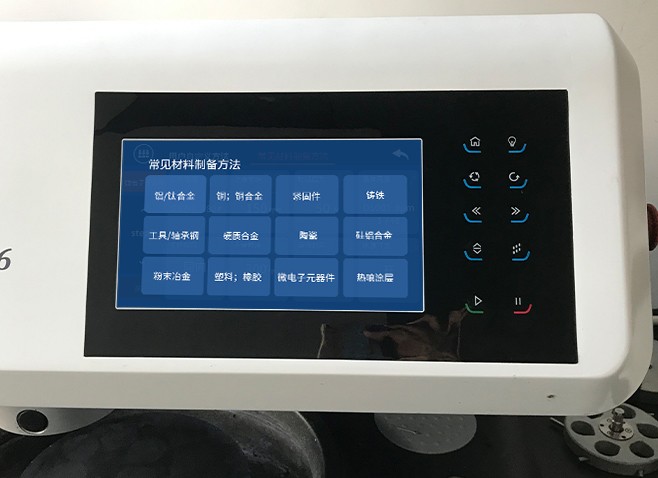

Method database

Automatic liquid filling system

Center & single-point loading in one

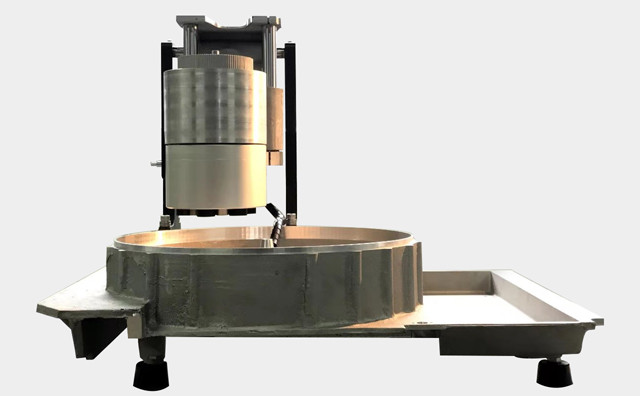

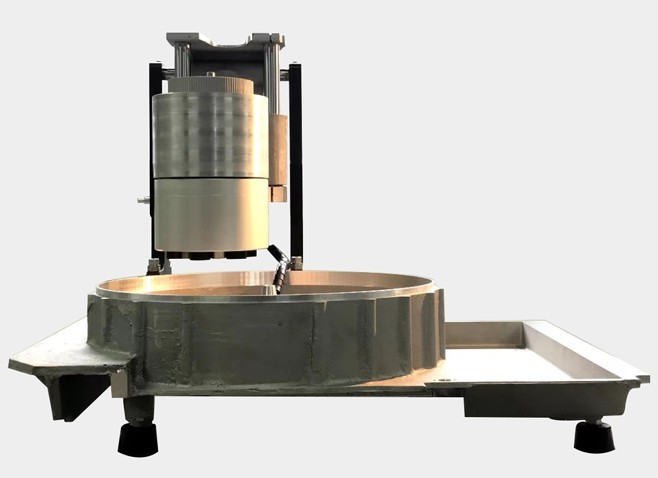

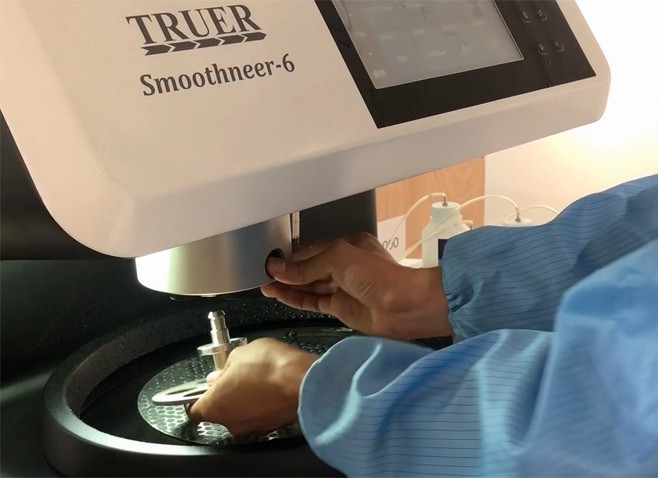

Smoothneer-6 (abbreviation is "S-6") is designed to present accurate and reproducible preparation results during metallographic testing. Smoothneer-6 adopts a sturdy and durable frame with dual-column design, equipped with an integrated sample moving head and automatic process control, additionally plus considerate and user-friendly operation mode, which makes Smoothneer-6 have strong sample grinding and polishing reliability and reproducibility.

The machine body adopts a frame-type with double-column structure directly connected to the base, ensuring the rigidity of the sample holder and the firmness of the entire device.

The high-performance guide system ensures the smooth movement of the holder. Therefore, the noise is minimized when perfectly preparing flat samples.

The shell has a thickened line design and is made of thickened high-quality engineering plastics, which is sturdy but not cold. It is strong and flexible with a strong sense of modernity.

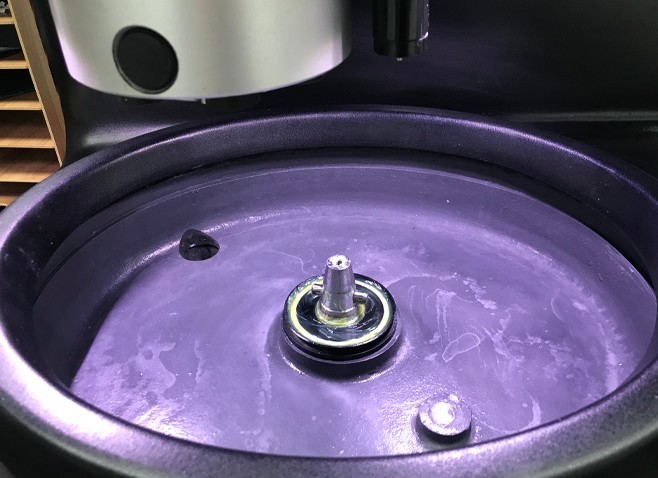

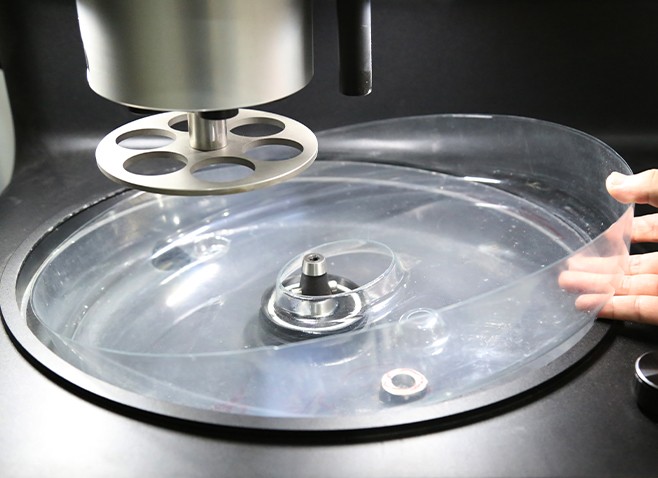

The base AlSiMg alloy thickened all-aluminum lower turntable has a sturdy body that is rust-proof and corrosion-resistant.。

The sturdy and durable sample moving head adopts a double-row structure and a large cast aluminum base, which not only effectively eliminates vibrations, but also ensures the best preparation results.

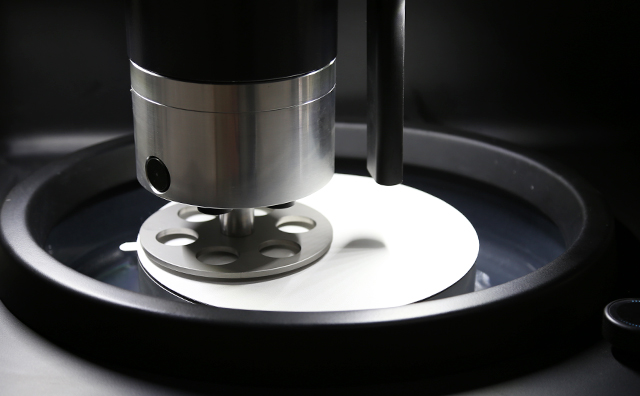

The semicircular design and starting point design of the clamp make it easy to put in and remove the sample. The clamp can be easily loaded and unloaded to make more thorough cleaning effect. The horizontal movement of the clamp in the X direction can be achieved by pressing a button to adapt to different sizes of work discs and maximize the use of grinding and polishing consumables. And the rotation direction of the clamp can be adjusted as needed to achieve the best preparation results.

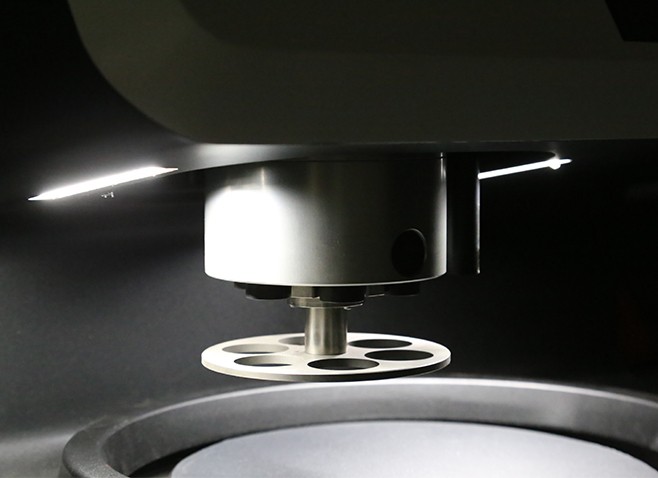

Precise start and stop control ensures the best preparation results and prevents potential sample damage. It is carefully protecting your samples from impact by the specially developed upper and lower turntable flexible start and stop technology, as well as the flexible pressure loading technology.

Built-in grinding rate sensor can measure the grinding amount in the range of 50~5,000μm, minimize grinding time and ensure sufficient material removal.

The system's pre-liquid design allows the magnetic disc to rotate slowly during pre-liquidation, so that the suspension/lubricant can be evenly distributed and retained on the magnetic disc.

One-touch switching between center or single-point loading means that the device can achieve better flatness.

Press the black button on the grinding and polishing head to easily switch the clamp.

Center loading can prepare samples of different sizes. The two methods are integrated, which means that more samples of different sizes can be prepared on the same machine, eliminating the trouble of switching back and forth between various devices.

Smoothneer-6 includes variety of preparation methods, covering all major material categories. Strive to achieve optimal performance and help you start working immediately.

Users can freely set 8 sample preparation parameters: sample rotation direction, upper and lower turntable speed, loading pressure, swing distance, combination of grinding & polishing liquid,dripping speed. Write a customized sample preparation program according to the characteristics of the material.

Smoothneer-6 system can store up to 6 preparation methods. Your exclusive sample preparation method can be stored with one click and called at any time to ensure that you always get a perfect sample preparation effect.

In the Smoothneer-6 system, you can also set the amount of polishing fluid required during the grinding process in addition to the system's own parameters. The automatic adding liquid function adjusts the amount of suspension/lubricant applied to improve reproducibility and control the waste of consumables.

When starting a new package, just calibrate the pump and Smoothneer-6 will do the same dosing of adding liquid every time. A variety of material preparation methods can achieve the same preparation results.

Smoothneer-6 has an automatic cleaning function for each pump in adding liquid . The liquid in the pump tube will return to the bottle and clean the section of the pipe from the back of the adding pump to the nozzle with tap water, eliminating blockage and ensuring that the pipe is clean and unobstructed.

Smoothneer-6 is a metallographic automatic grinding and

polishing machinethat can subvert usage habits.

It has strong function and supports center loading and

single-point loading;

It is convenient and efficient, and the sample preparation

parameters can be freely set.

The sample preparation method can be stored with one click.

And up to 6 samples with a diameter of 50mm can be prepared

at the same time with unique sample preparation efficiency.

Simple operation, high energy and efficiency, newbie can also

preparehigh-quality samples.

Demo

Smoothneer-6 (abbreviation is "S-6")

Smoothneer-6 (abbreviation is "S-6") is designed to present accurate and reproducible preparation results during metallographic testing. Smoothneer-6 adopts a sturdy and durable frame with dual-column design, equipped with an integrated sample moving head and automatic process control, additionally plus considerate and user-friendly operation mode, which makes Smoothneer-6 have strong sample grinding and polishing reliability and reproducibility.

|

NO |

ltem |

Parameters |

|

1 |

Input voltage |

AC220V 50Hz |

|

2 |

Dia.of G&P disc |

250mm( customize about $300mm) |

|

3 |

Rotation speed of of G&P disc |

20~400 r/min (customize max. 600r/min) |

|

4 |

Rotation speed of of G&P head |

0~150r/min |

|

5 |

Sample preparation time |

0~999 secods(can extend) |

|

6 |

Single point pressurization range |

5~60N |

|

7 |

Center pressurization range |

20~300N |

|

8 |

Input power |

1.3KW |

|

9 |

Outer size |

755 X 751 X 630mm |

|

10 |

N.W. |

83kg |

PDF

PDF

下载

下载

The customer's agreement is truly good! Whether it's products or services, the genuine feedback from customers is the source of our continuous improvement. Customer recognition is our unparalleled glory.

TOP