400 099 7576

400 099 7576Systematic product line

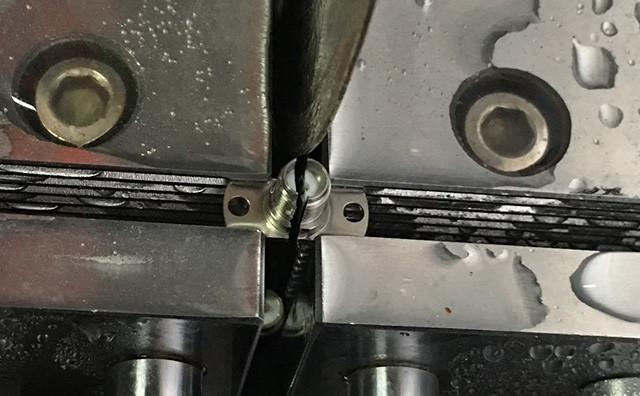

Precision - slim cutting seam technology

Durable,efficient,economical

Stable performance

Customized service (minimum order of 50 pieces)

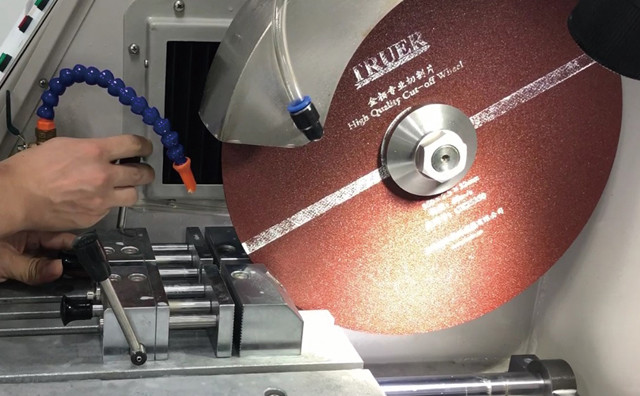

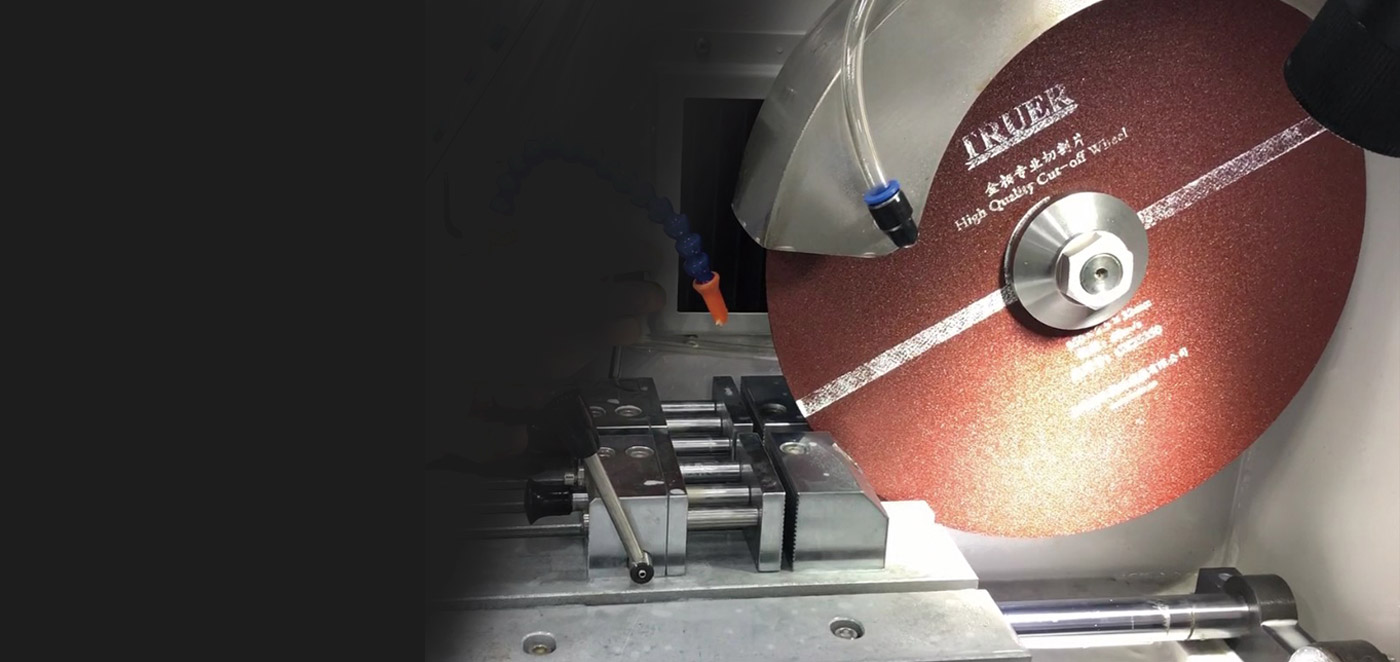

Truer has various cutting disc to meet the demand of different cutting of material in microscope analysis.Cutting seam is slim and flat,stable performance and durable.

A wide variety of cutting discs is to meet the needs of cutting in different materials of microscopic analysis. Cutting discs with different abrasives and binders are selected according to the material differences and hardness ratings of the target parts. Diamond or CBN (Cubic Boron Nitride) is used as abrasive when cutting materials with a hardness greater than HV 700.Al2O3 or SiC with resin binder is used to cut most metals.

A full range of cutting disc sizes and unconventional size customization services (minimum order of 50 pieces) can be provided to meet special cutting needs.

The cutting disc adopts tireless rolling one-step forming technology.The three characteristics of the cutting blade are flat, high-strength, and thin combined with a new high-strength adhesive. It can still achieve the transmission of large cutting torque and it is flat and has no jitters at the lowest thickness.

From now on, you can accurately position and cut accurately

Stable cutting, consistent and long-lasting.

To ensure the stable performance of each cutting disc,the cutting discs are made of carefully selected materials with strict control over the purity, particle size and quality of the abrasives and the binder, combined with a reliable and consistent preparation process. The sample will not be overheated and damaged due to the fluctuation of the cutting disc during cutting whether the the material is hardness or softness, the shape is changeable. This creates good conditions for the next preparation step.

The combination of high-purity abrasive grains and perfect craftsmanship makes the cutting disc more durable.

Choosing the suitable cutting disc is not only a guarantee of preparation quality, but also the best way to save time and consumables. Choosing the right cutting disc can reduce the subsequent preparation steps of the prepared surface.The sample takes less time and costs in preparation .

The cutting disc series of Truer has stable cutting and lasts for a long time.

The cutting disc is made of exquisite materials and advanced technology.

High-purity imported abrasives and industrial fine resins are selected. The

particle size distribution and formula ratio of the abrasive are strictly

controlled,combined with advanced blending technology and one-step

molding technologyto achieve uniform density, flatness and durability of

the cutting blade. Ensure fast and stable cutting, precise and controllable

cutting seams, bright and flat cut surfaces, and reduced cutting burnout.

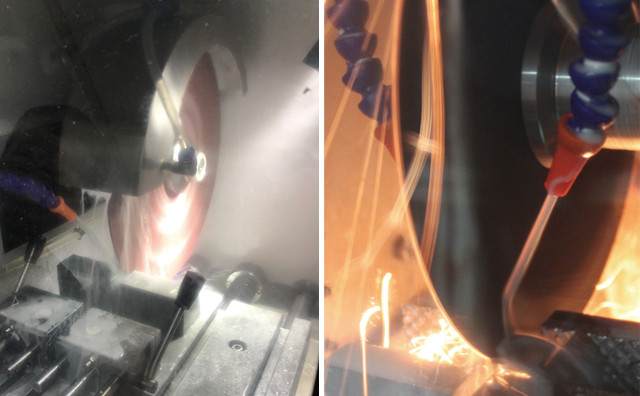

Demo

Alumina Al2O3 Precision Cutting Disc

Used with precision cutting machines,cutting of various non-ferrous metals, PCB circuit boards,etc.

Alumina Al2O3 Alumina Al2O3 High Hardness Material Cutting Disc

Cut the medium hardness or extremely hard black metal (such as steel,carbon steel,etc)

Silicon Carbide SiC Soft and Tough Material Cutting Disc

Cut the soft non-ferrous metals(such as aluminum,copper,HV30-400) or cut the high toughness metal(such as titanium etc, HV70-400)

Cut-off Wheel

Components: abrasive + adhesive

Cutting purpose: extract the analysis area and make the sample have a workable shape and size..

The most commonly used method in metallographic sample preparation is abrasive wet cutting. The coolant flushes the cutting disc to avoid thermal damage and remove the grinding chips to ensure the maximum chip removal during cutting. The selection of various cutting discs ensures that all materials will not change their organizational structure due to overheating or deformation during cutting, and ensures the maximum service life of the cutting disc.

|

Soft and Tough Material Cutting Disc (Silicon carbide sic resin key) |

|||

|

Miodel |

Siz0 |

Package Qty |

Application Fidld |

|

CT03100 |

100×0.3×12.7mm |

10 pcs/box |

|

|

CT05125 |

125×0.5×12.7mm |

10 pcs/box |

|

|

CT05150 |

150×0.5×12.7mm |

10 pcs/box |

|

|

CT06152 |

152×0.6×12.7mm |

10 pcs/box |

|

|

CT05175 |

175×0.5×12.7mm |

10 pcs/box |

|

|

CT10200 |

200×1.0×32 mm |

10 pcs/box |

|

|

CT08205 |

205×0.8×22 mm |

10 pcs/box |

|

|

CT12230 |

230×1.2×32 mm |

10 pcs/box |

|

|

CT15250 |

250×1.5×32 mm |

10 pcs/box |

|

|

CT20250 |

250×2.0×32 mm |

10 pcs/box |

|

|

CT15300 |

300×1.5×32 mm |

10 pcs/box |

|

|

CT20300 |

300×2.0×32 mm |

10 pcs/box |

|

|

CT25300 |

300×2.5×32 mm |

10 pcs/box |

|

|

CT20350 |

350×2.0×32 mm |

10 pcs/box |

|

|

CT25350 |

350×2.5×32 mm |

10 pcs/box |

|

|

CT30400 |

400×3.0×32 mm |

10 pcs/box |

|

|

CT35450 |

450×3.5×32 mm |

10 pcs/box |

|

|

CT40500 |

500×4.0×32 mm |

10 pcs/box |

|

|

High Hardness Material Cutting Disc (Alumina Ai203 resin key) |

|

||

|

Miodel |

Size |

Package Qty |

Application Fidld |

|

CY03100 |

100×0.3×12.7mm |

10 pcs/box |

|

|

CY05125 |

125×0.5×12.7mm |

10 pcs/box |

|

|

CY05150 |

150×0.5×12.7mm |

10 pcs/box |

|

|

CY06152 |

152×0.6×12.7mm |

10 pcs/box |

|

|

CY05175 |

175×0.5×12.7mm |

10 pcs/box |

|

|

CY10200 |

200×1.0×32 mm |

10 pcs/box |

|

|

CY08205 |

205×0.8×22 mm |

10 pcs/box |

|

|

CY12230 |

230×1.2×32mm |

10 pcs/box |

|

|

CY15250 |

250×1.5×32 mm |

10 pcs/box |

|

|

CY20250 |

250×2.0×32 mm |

10 pcs/box |

|

|

CY15300 |

300×1.5×32 mm |

10 pcs/box |

|

|

CY20300 |

300×2.0×32 mm |

10 pcs/box |

|

|

CY25300 |

300×2.5×32 mm |

10 pcs/box |

|

|

CY20350 |

350×2.0×32 mm |

10 pcs/box |

|

|

CY25350 |

350×2.5×32 mm |

10 pcs/box |

|

|

CY30400 |

400×3.0×32 mm |

10 pcs/box |

|

|

CY35450 |

450×3.5×32 mm |

10 pcs/box |

|

|

CY40500 |

500×4.0×32 mm |

10 pcs/box |

|

PDF

PDF

下载

下载

The customer's agreement is truly good! Whether it's products or services, the genuine feedback from customers is the source of our continuous improvement. Customer recognition is our unparalleled glory.

TOP