400 099 7576

400 099 7576High grinding rate and removal rate

High grinding rate and removal rate

Excellent suspension effect

The unique QMOVE diamond suspension has a high grinding rate and removal rate. Under the condition of the same grinding and polishing quality, it saves 30% of dosage and 60% of time compared with ordinary polishing fluid.It makes sample preparation better, faster and more economical.

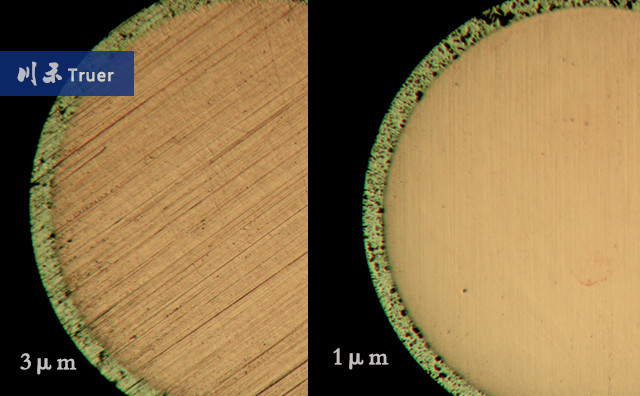

Particle size selection range of QMOVE diamond suspension is from coarse to fine to meet the every step requirement from sample preparation of client.

To ensure the best polishing effect at the lowest cost,the diamond grain size and shape tolerances are strictly controlled.

QMOVE polycrystalline suspension is a full-performance product, especially suitable for the needs of extremely soft or extremely hard samples that are difficult to prepare.

For extremely soft materials, the rapid grinding of polycrystalline diamond can quickly remove scratches in a short time while ensuring that the material surface does not deform, which is a "gentle" scratch removal;

For extremely hard materials, it often takes a long time to remove the upper scratch, which is easy to cause rounded corners and affect the subsequent microscopic focus. The high grinding efficiency of polycrystalline diamond can quickly complete the polishing step and prevent the generation of rounded corners, which is a "powerful" grinding.

Advanced preparation technology enables it to have excellent properties of easy dispersion and easy bonding.

The diamond abrasive particles in the QMOVE suspension are always in a uniform floating state, with excellent dispersibility.It can be well attached to the grinding and polishing carrier (such as grinding disc, sandpaper, polishing cloth). Due to its strong bonding, the diamond abrasive particles will not be lost even when the grinding and polishing equipment is running at high speed, and the loss is extremely low.

Compared with ordinary polishing fluid, under the condition of equal grinding and polishing quality, the amount is saved by 30% and the time is saved by 60% because QMOVE has a high grinding rate and removal rate.

High-purity diamond is selected as abrasive, which has extremely high hardness, sharp edges, and high grinding rate for both hard and soft materials.

Each diamond abrasive grain of QMOVE is made by international advanced airflow crushing process, which fully guarantees the purity and grinding performance of diamond. At the same time, QMOVE is produced with strict classification particle size. The diamond particle morphology is spherical octahedron, with precise particle size and narrow tolerance range, which makes the grinding effect better, the scratch removal rate higher, and the new scratches less.

The use of QMOVE will not roll the sample surface and will not produce an interference layer on the material surface.

QMOVE suspension contains a certain amount of cooling and lubricating components.It realizes the effective combination of diamond's long-lasting wear-resistant grinding and polishing force with key performances such as cooling and lubrication. It completely reduce the possibility of thermal damage during the grinding and polishing process,ensuring the smoothness and flatness of the sample surface.

The "three-in-one" component improves the grinding and polishing quality while being easy to use, saving time and cost for users.

Compared to the serious sedimentation problems of many domestic suspensions, Truer’s QMOVE suspension series products have high-standard suspension pedigree:

Suitable for manual grinding and polishing, and also suitable for automatic liquid addition system.

DS001 polycrystalline diamond suspension polishing

DS002 monocyrstalline diamond suspension polishing

DS001-C polycrystalline diamond suspension polishing alcohol

QMOVE Diamond Suspension

Unique QMOVE diamond suspension makes sample preparation better, faster and more economical

Polycrystalline diamond--natural diamond, the sharpest abrasive as known

Polycrystalline diamond suspension--metallographic abrasive with the most efficient grinding rate

Fast | Durable | Lubricating

Quickly removable rate

Durable and wear-resistance

Good lubricating

The polycrystalline diamond series suspension is the product with the highest grinding efficiency among the Truer’s QMOVE suspension system.

Each diamond is carefully selected, strictly graded, and the advanced preparation process makes it suitable for different grinding and polishing carriers to meet the preparation needs of different samples.

It is not only suitable for metallographic and lithology grinding and polishing, but also suitable for grinding and polishing of high-smooth surfaces of various ferrous and non-ferrous metals, ceramics, composite materials, gemstones, instruments, optical glass and other products.

|

Model |

Product Name |

Abrasive Type(um) |

Package |

Application Field |

|

DS001 |

polycrystalline diamond suspension polishing |

0.25μm、0.5μm、1μm、1.5μm、2.5μm、3μm、3.5μm、5μm、6μm、7μm、9μm |

500ML/Bottle 2.5L/Drum 5L/Drum |

Polycrystalline diamond is composed of countless tiny crystals, which canproduce a huge number of tiny cutting edges. In the process ofmetallographic sample preparation, these edges can produce highgrinding rates and shallow scratches. Therefore, it is more efficient and hasbetter use effect than monocrystalline. |

|

DS002 |

monocyrstalline diamond suspension polishing |

0.25μm、0.5μm、1μm、1.5μm、2.5μm、3μm、3.5μm、5μm、6μm、7μm、9μm、10μm、14μm、15μm、20μm、28μm、40μm |

500ML/Bottle 2.5L/Drum 5L/Drum |

Monocrystalline diamond is short and solid in shape, and can only providea few cutting edges which is suitable for general metal materials and soft materials. |

|

DS001-C |

polycrystalline diamond suspension polishing alcohol |

0.25μm、0.5μm、1μm、1.5μm、2.5μm、3μm、3.5μm、5μm、6μm、7μm、9μm |

500ML/Bottle 2.5L/Drum 5L/Drum |

Alcohol,water conten <0.5%w/wUsed to prepare materials that will react with water to misleading thestructure analysis of the material .When preparing water-sensitive materials, oil-based products are usuallyrequired, which often causes oil stains on samples and equipment.DS001-Csuspension overcomes the problem of difficult cleaning of oilstains and is easier to use. |

|

|

||||

The difference between monocrystalline and polycrystalline

Monocrystalline:artificial diamond

The crystals are bonded together by saturated and directional covalent bonds, which have extremely high hardness and wear resistance. Single diamond contains several sharp edges, which can quickly remove scratches on the working surface.

Polycrystalline:similar with nature diamond

The structure is very similar to natural Carbonado, which is composed of spherical microcrystals with a size of only 3-10mm.

Compared with single crystal diamond, polycrystalline diamond has more crystal edges and grinding surfaces, and each crystal edge has cutting ability. The contact grinding probability between diamond and sample surface is greatly increased, which greatly improves the grinding rate.

At the same time, polycrystalline diamond has unique toughness and self-sharpening. During the grinding process, coarse particles will be broken into many small particles to avoid scratches on the workpiece surface by sharp edges and corners, which not only ensures the polishing quality of the sample surface, but also improves the grinding and cutting efficiency.

PDF

PDF

下载

下载

The customer's agreement is truly good! Whether it's products or services, the genuine feedback from customers is the source of our continuous improvement. Customer recognition is our unparalleled glory.

TOP