400 099 7576

400 099 7576 2020-10-30

2020-10-30

The ultimate goal of metallographic sample preparation is to prepare a flat mirror surface for observation after corrosion or direct observation. The importance of grinding and polishing is obvious. If cutting and mounting are the preliminary steps of sample preparation, then grinding and polishing are the most important steps in the sample preparation process. Friends who are fortunate enough to avoid the cutting and mounting processes should be more cautious and careful in the grinding and polishing stage, otherwise the work will fail.

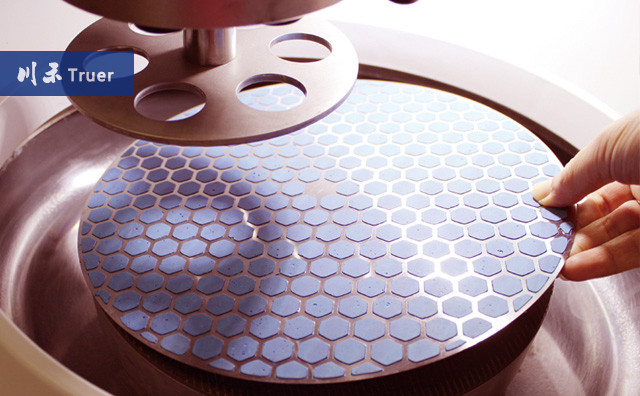

Grinding and polishing are divided into two stages: flattening and polishing. During the cutting process of the sample, due to the high-speed rotation and impact of the saw blade, the front surface of the cut surface will have a certain degree of material deformation and burning, and the surface formed by the cut mark will be rough and uneven. The so-called flattening is to quickly remove the surface of the cut rough surface through large-grain abrasives to obtain a flat fresh surface, which provides a basis for subsequent polishing. Generally speaking, the diameter of the abrasive grains in the flattening stage is more than 100 microns, so the basic scratches are naturally around 100 microns. The process of polishing is to gradually reduce the size of the scratches, and finally within 1 micron, which is invisible under conventional optical magnifications and suitable for direct observation and analysis, or observation and analysis after corrosion. It can be seen that grinding and polishing is a fine material surface grinding process, and the grinding medium has two sources, grinding disc and suspension. Especially in the initial stage of polishing, the abrasive source is the grinding disc. The grinding disc surface can be sandpaper or a grinding disc with diamond or other types of abrasive grains. This process can also be supplemented with suspension to enhance the grinding effect. In the later stages of polishing, the abrasive disc is a different type of fabric that does not contain the abrasive itself, but can store the abrasive from the suspension.

The grinding and polishing process generally includes three grinding and polishing steps: rough grinding, fine grinding and polishing. For samples with higher requirements, polishing must be divided into two steps: rough polishing and fine polishing to achieve the ideal observation surface. A thorough cleaning process must be performed at the end of each step to eliminate the interference of residual abrasive particles in the previous step with the next step.

Rough grinding: that is, grinding flat, removing cutting scratches, finding the reference surface, and controlling the scratches to about 100 microns.

Fine grinding: further reducing the size of scratches to about 9 microns to provide a suitable surface for polishing.

Rough polishing: eliminate scratches visible to the naked eye and control the scratches to about 3 microns.

Fine polishing: eliminate optical microscope scratches and control the scratches to less than 1 micron.

There are many factors affecting the grinding and polishing process. If we want to ensure high-quality grinding and polishing, we must quantify the variables, and all open nodes can achieve quantitative control. For example, the equipment supports two modes: center loading and single-point loading, disk speed, gripper steering and speed, gripper projection position on the disk, loading pressure, grinding and polishing time, suspension type, filling speed, disk type at each step, etc. If quantitative control is achieved in all the above links, the accidental factors for successful grinding and polishing will be greatly reduced, sample preparation will shift from dependence on people to dependence on equipment, and the technical entry threshold will be lowered.

After the above links realize equipment control and process control, for samples of specific materials, the main task of the metallographic technician is to find out the most optimized parameter combination, and then solidify it and share it with others. This process is destined to be repeated exploration and trial, and it is inevitable to take a lot of detours. The most labor-saving way is to outsource this work to a professional company. Domestic professional companies such as Shanghai Truer have more than ten years of experience in commissioned sample preparation, accumulated a lot of sample preparation information, and established a special database, which can quickly obtain the best sample preparation plan.

All microscopic analyses are the accumulation and crystallization of countless details, and the same is true for metallographic analysis. Even the most insignificant errors may create obstacles for subsequent observations. Industry practitioners must be in awe and pursue perfection.

Shanghai Truer Company has been deeply involved in the metallographic testing industry for decades, and has long practiced the concept of exquisite metallography. It is a leading metallographic solution provider in China. Truer takes international giants as benchmarks, faces difficulties, concentrates on research, overcomes key equipment and consumables that restrict the development of the industry, and creates a complete metallographic industry chain integrating equipment, consumables and sample preparation training; the company is equipped with a cutting-edge metallographic laboratory and has a team of highly qualified experts. For more than ten years, it has provided metallographic analysis and sample preparation training services to thousands of customers, and provides customized metallographic laboratory solutions.

If you have any metallographic questions, you can get in touch with them to get the information you want.

TOP