400 099 7576

400 099 7576 2020-10-30

2020-10-30

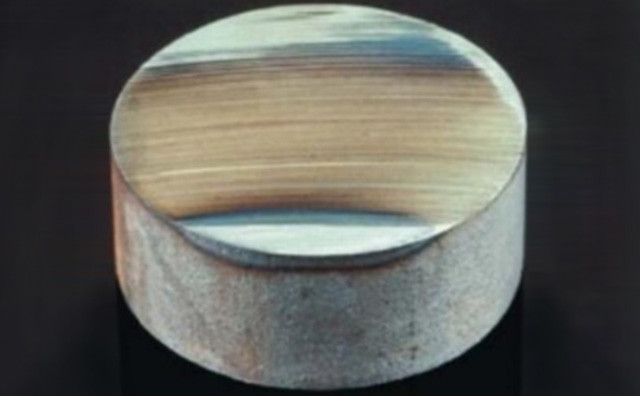

Metallographic sample preparation is a technical job, which requires the sample maker to understand the basic conditions of the target material, such as the mechanical properties of the material such as hardness and strength, the key observation points, and the taboo requirements of the target material. Only then can the appropriate sample preparation process be formulated based on these characteristics.

Generally speaking, metallographic sample preparation includes three steps: cutting, mounting and grinding and polishing. As the name implies: Cutting is to cut the original sample to obtain the most representative target analysis surface. Mounting is to put the cut sample into the mounting resin to form a standard sample for subsequent grinding and polishing. Grinding and polishing is to flatten the target analysis surface and eliminate scratches for later microscopic observation. Cutting is the initial step of sample preparation and directly determines whether the sample preparation is successful. The basic requirements for cutting are as follows:

1. Develop a reliable clamping plan.

2. Select a suitable cutting disc.

3. Set appropriate cutting parameters.

Formulate a clamping plan

1. Whether it is horizontal clamping of a push clamp or vertical clamping of a finger clamp, try to choose a larger and flatter surface as the pressure-bearing surface to ensure that the clamping force is stable.

.jpg)

2. Try to avoid the curved surface when the cutting blade lands, because the cutting blade has a certain deformation ability, and the curved surface will induce the cutting direction to deviate. The deviated cutting seam will further increase the deviation of the saw blade, causing the cutting blade to break, and even cut the workbench. l Predict whether the part is unstable at the end of the cutting. If it is unstable, it will damage the cutting surface again, or even break the saw blade. Especially for parts clamped at both ends.

3. Platform corrosion

.jpg)

4. Choose the right cutting blade

1.Choose the type of cutting blade according to the hardness of the material, such as aluminum oxide, silicon carbide, boron nitride and diamond. Check the condition of the cutting blade, especially the reused cutting blade, check whether the outer edge is chipped, etc., and estimate whether the new saw blade diameter can cover the expected cutting range. If the outer diameter is reduced significantly, it is also necessary to consider whether the speed needs to be adjusted to compensate for the actual linear speed. Set cutting parameters 1.Calculate the cutting speed and set the rotation speed according to the type and hardness of the target material and the effective directness of the cutting blade.

2.Set the cutting angle: If it is manual cutting, it is best to adjust the position of the workbench so that most of the cutting parts are at 45°.

3.Set the feed mode: If it is automatic cutting, it is necessary to set the appropriate feed speed and distance, and try to choose a lower feed speed to ensure that the sample will not be burned; for high-hardness and high-strength samples, consider activating the intelligent cutting function, that is, the cutting power is adaptive to the saw blade speed to prevent burning the sample and breaking the saw blade. After cutting, check whether the analysis surface is flat and whether there is any burn damage. After cleaning and drying, proceed to the next process. If you want to do your job well, you must first sharpen your tools. Reliable and powerful cutting equipment is the basic prerequisite for cutting; a variety of clamping tools, cutting disc types and cutting coolant varieties are important guarantees for cutting; finally, combined with skilled experience and skills, you can get an ideal cutting sample.

If you have any troubles in metallographic sample preparation, you may wish to consult the professional metallographic technicians of Shanghai Truer Company, or entrust them to prepare samples. Truer Company has more than ten years of experience in complete analysis and has handled thousands of difficult cases.

I believe it will be helpful to you. As a professional metallographic solution provider in China, Shanghai Truer Industrial Development Co., Ltd. takes international giants as benchmarks, faces difficulties, concentrates on research, overcomes key equipment and consumables that restrict the development of the industry, and creates a complete metallographic industry chain integrating equipment, consumables and sample preparation training; the company is equipped with a cutting-edge metallographic laboratory and has a high-quality team of experts. For more than ten years, it has provided metallographic analysis and sample preparation training services to thousands of customers, and provides customized metallographic laboratory solutions.

TOP