400 099 7576

400 099 7576 2020-10-30

2020-10-30

Metallographic sample preparation is a technical job, especially cutting. The quality of cutting directly determines whether the entire sample preparation process can be successful, so it is very critical. Metallographic cutting is to cut the original sample to obtain the most representative target analysis surface. Cutting is essentially the process of removing the slit material. The cutting blade rotates at high speed to make the hard abrasive protruding on the surface impact the sample, and the sample is cut by self-loss.

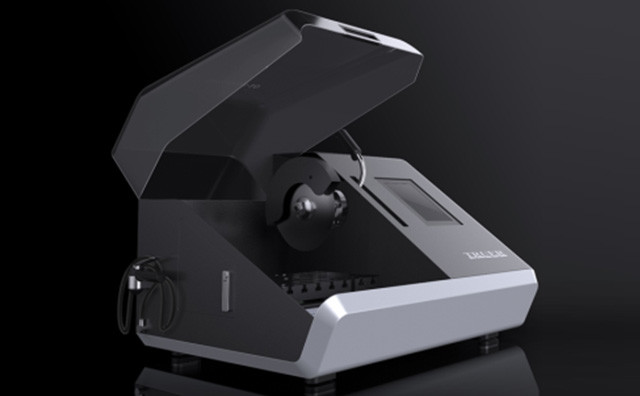

The cutting process is completed by the cutting machine. A stable, reliable and powerful cutting machine is a necessary prerequisite for the cutting process. With the continuous advancement of technology, the functions of metallographic cutting machines are constantly being innovated, especially the intelligent cutting function with power adaptation as the mainstream, which greatly improves the cutting quality. Taking Shanghai Truer , a benchmark metallographic equipment company in China, as an example, they launched the Smartcut cutting machine with intelligent cutting function. The following editor will introduce the functional characteristics of intelligent cutting.

1. Power detection:

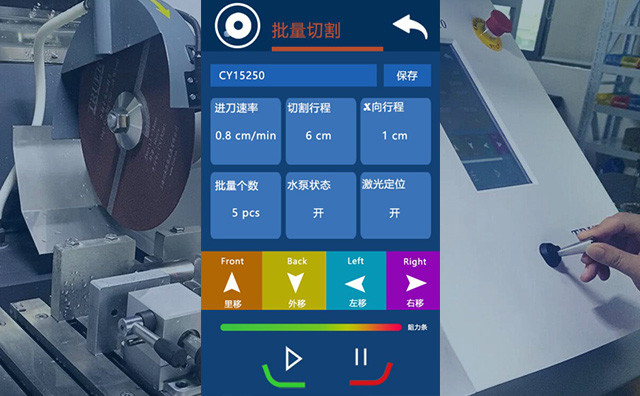

The device is equipped with an automatic power detection function and displays it in real time on the screen in the form of a power bar.

2. Over-limit warning

When the power is running within the safe range set by the system, the power bar will be displayed in green. When it exceeds the preset safety value, the power bar will be displayed in warning red. When it reaches the set limit value, it will automatically shut down.

3. Platform linkage

Real-time power is linked to the workbench feed. When the power exceeds the preset safety value, the workbench feed is reduced or stopped until the power returns to below the safety value, and then the workbench feed is resumed. Such a linkage mechanism is always activated, which can effectively prevent the sample from overheating and burning, and can also protect the cutting disc from overload and breakage.

In short, if you want to do your job well, you must first sharpen your tools. Reliable and powerful cutting equipment is the basic prerequisite for cutting. Equipment is a long-term asset, not a disposable item, and its quality can only be seen over time. When evaluating equipment, we must examine all aspects and cannot emphasize the price alone.

As a benchmark enterprise in the domestic metallographic industry, Shanghai Truer Company has developed various types of cutting machines with superior design, authentic materials, superior workmanship, and reasonable prices. It is your only supplier of cutting machines and other metallographic equipment.

As a professional metallographic solution provider in China, Shanghai Truer Industrial Development Co., Ltd. takes international giants as benchmarks, faces difficulties, concentrates on research, and overcomes key equipment and consumables that restrict the development of the industry, creating a complete metallographic industry chain integrating equipment, consumables and sample preparation training; the company is equipped with a cutting-edge metallographic laboratory and has a team of highly qualified experts. For more than ten years, it has provided metallographic analysis and sample preparation training services to thousands of customers, and provided customized metallographic laboratory solutions.

TOP