400 099 7576

400 099 75761、Cutting

Alloy white cast iron is very hard (HV6 0 0). Regardless of its hardness, diamond cutting wheels are not suitable for cutting white cast iron. It is recommended to cut by cubic boron nitride grinding wheels. For cutting cast iron with graphite, it is recommended to choose aluminum oxide cutting discs according to the hardness of the cast iron to be cut. For large-scale cutting, automatic cutting is more efficient than manual cutting.

Alumina resin cutting disc SmartCut-10 manual and automatic cutting machine

2、Mounting

Hot inlay is recommended for cast iron inlay. For soft and medium-hard cast iron, UNIWARM universal hot inlay resin is recommended; for harder cast iron, EDGWARM edge-preserving hot inlay resin is more suitable.

Edge-protection Hot Mounting Resin Penetration-20 Auto Dual-station Hot Mounting Machine

3、Grinding and polishing

Graphite is soft and difficult to maintain its actual shape and size. Ferrite and/or austenite cast iron matrix is more prone to deformation and scratches.

GD-Dia Diamond Magnetic Grinding Disc Metallographic Sandpaper

Harder white cast iron and ADI cast iron can be coarse ground with diamond grinding discs (GD-Dia 220#) and fine ground with diamond grinding discs GD-Sof. Soft and medium-hard cast iron (with ferrite, austenite or pearlite matrix) can be coarse ground with silicon carbide sandpaper and fine ground with diamond grinding discs GD-Sof. Diamond grinding discs can keep the sample flatter than silicon carbide sandpaper without protruding graphite.

Alcohol-based diamond suspension Polishing lubricant coolant

It is recommended to use anhydrous alcohol-based diamond suspension and alcohol-based polishing lubricant coolant because cast iron is easily oxidized during polishing,

1、White cast iron

|

The step of grinding & polishing |

Coarse Grinding |

Fine Grinding |

Diamond Coarse Polishing |

Diamond Fine Polishing |

Diamond Final Polishing |

|

|

1 |

Surface |

PCM canvas |

PCV Red Short velvet |

|||

|

2 |

Abrasive Granularity |

220# |

|

9μm |

3μm |

1μm |

|

3 |

Polishing/ Lubricant |

Alcohol, polishing lubricantcoolant |

Alcohol, polishing lubricantcoolant |

|||

|

4 |

Pressure |

30N |

25N |

25N |

20N |

15N |

|

5 |

Rotation Speed |

300 |

300 |

150 |

150 |

150 |

|

6 |

Time/'min. |

3 |

4 |

3 |

2~5 |

2~3 |

2、Cast iron with graphite

|

The step of grinding & polishing |

Coarse Grinding |

Fine Grinding |

Diamond Coarse Polishing |

Diamond Fine Polishing |

Diamond Final Polishing |

|

|

1 |

Surface |

SiC sandpaper |

PCV Red Short velvet |

PCX Rubber cloth |

||

|

2 |

Abrasive Granularity |

400# |

|

3μm |

1μm |

0.05μm |

|

3 |

Polishing/ Lubricant |

water |

water |

|||

|

4 |

Pressure |

30N |

25N |

25N |

20N |

15N |

|

5 |

Rotation Speed |

300 |

300 |

150 |

150 |

150 |

|

6 |

Time/'min. |

2 |

4 |

3 |

2~5 |

2~3 |

The above recommended parameters are taken from: Metallographic preparation method of Ø30 mm cast iron with Ø250 mm working plate on automatic grinding and polishing machine Smoothneer-6.

Etching

Graphite-containing cast iron is not suitable for electrolytic polishing because the graphite will be etched away by the electrolyte. However, if the microstructure of the substrate needs to be quickly identified, electrolytic polishing and etching can be used

Common cast iron etching agents are as follows:

|

Composition, usage and instructions of commonly used etchants for cast iron |

|

No. |

Composition |

Usage and Instructions |

|

1 |

Nitric acid 0.5~6.0ml Ethanol 96~99.5mLL |

The cast iron matrix structure is displayed, and the etching time is from afew seconds to 1 minute. For high-dispersion structures, low-concentration solutions can be used for etching to slow down thecorrosion rate and thus improve the clarity of the structure. |

|

2 |

Picric acid 3~5g |

Shows the cast iron matrix structure. The corrosion rate is relatively slow,. |

|

3 |

Copper chloride 1g Anhydrous ethanol 100mL |

Display the interface of cast iron eutectic group. Use absorbent cotton todip the solution and evenly apply it on the polished surface of thesample. The etching speed is slow and the effect is good. |

|

4 |

Copper chloride 3g |

Shows the interface of cast iron eutectic, and the etching speed is faster |

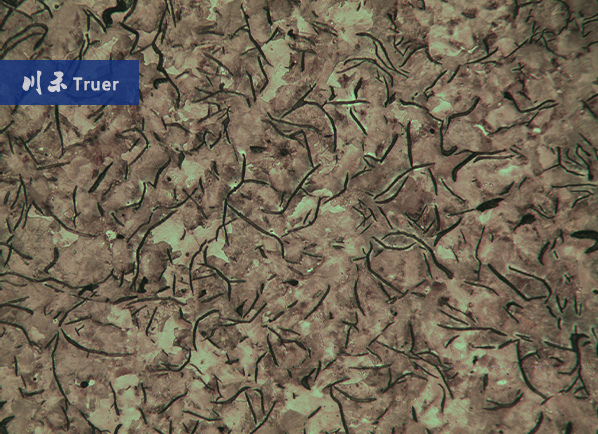

Organization Appreciation

.jpg)

Ductile Iron 200X

.jpg)

Ductile Iron 50X

.jpg)

Gray cast iron after corrosion 100X

*The above pictures may not be reproduced without permission, otherwise legal liability will be pursued.

TOP