400 099 7576

400 099 7576Difficulty in sample preparation: very soft, easy to cause scratches; ;easy to cause scratches; very thin, easy to over-grind.

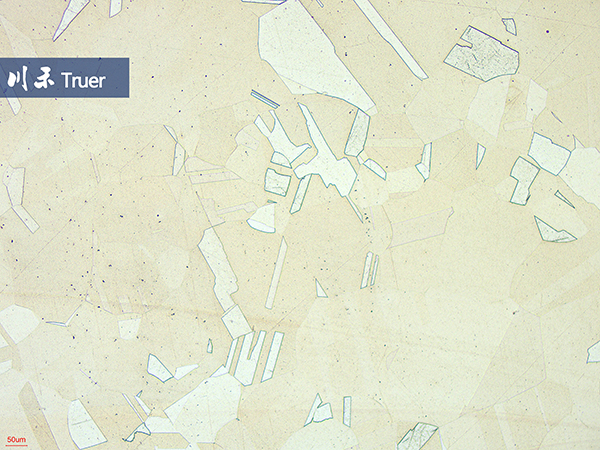

Customer goal: After corrosion, the grain boundary is clearly visible.。

.jpg)

.jpg)

0.1mmthick copper foil is pasted with wax Grinded sample

Pure copper foil after corrosion 200X 200X

*The above pictures may not be reproduced without permission, otherwise legal liability will be pursued.

Fixing:

Truer hot melt wax stick Hot melt wax can be melted after heating and the sample can be easily removed. Image

* After the standard sample is heated in the oven at 70 degrees, take it out, apply the hot melt wax stick evenly on the standard sample, place the copper foil, and fix it firmly after the sample cools down.

Sample preparation:

Smoothneer-6 Metallographic Automatic Grinding and Polishing Machine PCX Porous Neoprene Polishing Cloth

.jpg)

OS001-JPAlumina Nano-Suspension Grinding and Polishing Liquid 0.05μmμm Scratch-free sample

|

The step of grinding & polishing |

Coarse Grinding |

Fine Grinding |

Diamond Medium Polishing |

Diamond Fine Polishing |

Oxide Final Polishing |

|

|

1 |

Surface |

|||||

|

2 |

Abrasive Granularity |

1200# |

4000# |

3μm |

1μm |

0.05μm |

|

3 |

Polishing/Lubricant |

water |

water |

|||

|

4 |

Pressure |

15N |

15N |

15N |

10N |

10N |

| 5 | Upper Rotation Speed | 150 | 150 | 150 | 150 | 150 |

|

6 |

Lower Rotation Speed |

300 |

300 |

150 |

150 |

150 |

|

7 |

Time/sec. |

120 |

120 |

180 |

120 |

240 |

The above recommended parameters are taken from: Smoothneer-6 Metallographic Automatic Grinding and Polishing Machine Sample Preparation Method.

TOP