400 099 7576

400 099 7576

Key points in sample preparation:

Compared with other metals, titanium has a relatively low thermal conductivity, so water cooling must be used when cutting the sample to prevent local overheating. In addition, the cutting rate and feed rate of the cutting blade should be reduced. Materials are divided into soft and hard. In addition to silicon carbide cutting blades, resin diamond cutting blades with relatively weak bonding strength can also be used for cutting.

Hard mold cold mounting Sample after mounting

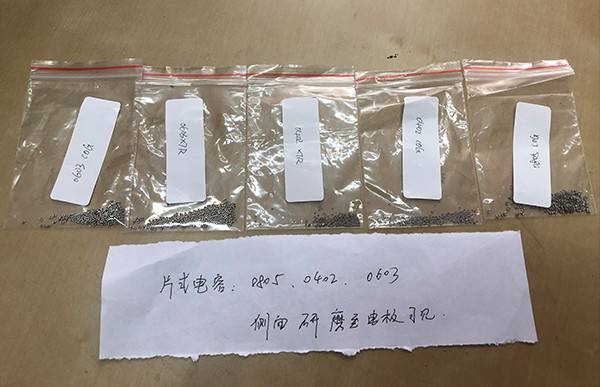

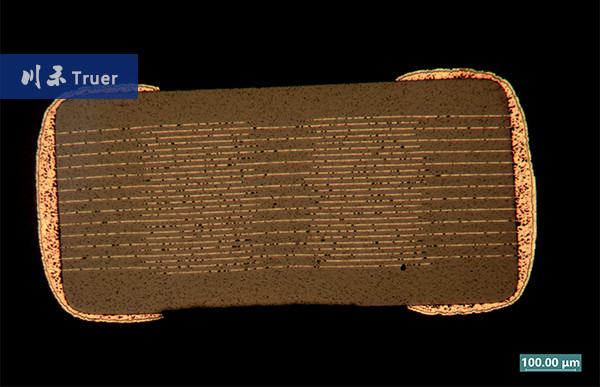

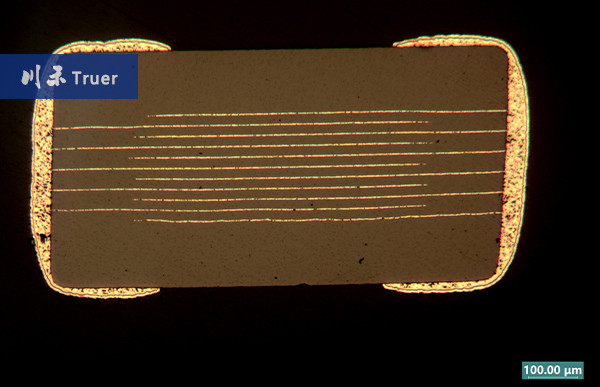

Chip capacitor 0402 7R 100X Chip capacitor 0402 COG 100X

.jpg)

Chip capacitor 0603 7R 50X Chip capacitor 0603 7R 100X

.jpg)

.jpg)

Chip capacitor 0603 COG 50X Chip capacitor 0805 COG 50X

In view of the small size of chip capacitors, it is difficult to grasp the specific observation surface and it is easy to over-grind. We used the quantitative grinding function of Smoothneer-6, which can accurately control the grinding removal amount of the sample by 50µm~5000µm.

Smoothneer-6 Metallographic Automatic Grinding and Polishing Machine Grinding Amount Control Interface

The following is the sample preparation method::

Mounting:

MC003 Vacuum-free Clear Cold Mounting Kit The samples after mounting

Grinding & Polishing:

|

The step of grinding & polishing |

Coarse Grinding |

Fine Grinding |

Diamond Coarse Polishing |

Diamond Fine Polishing |

Diamond Final Polishing /oxide polishing |

|

|

1 |

Surface |

SiC sandpaper |

SiC sandpaper |

PCY Wool fabric |

PCV red short velvet |

PCX Neoprene |

|

2 |

Abrasive Granularity |

400# |

800#、1200#、4000# |

3μm |

1μm |

0.05μm |

|

3 |

Polishing/ Lubricant |

water |

water |

DS001 High performance polycrystalline diamond suspension |

DS001 High performance polycrystalline diamond suspension |

OS001-JP fine polishing liquid mu0.05 |

|

4 |

Pressure |

30N |

25N |

25N |

20N |

15N |

|

5 |

Rotation Speed |

300 |

300 |

150 |

150 |

150 |

|

6 |

Time/min. |

1 |

2 |

3~5 |

2~3 |

2~5 |

The above recommended parameters are taken from: Preparation method of Ø30 mm copper and copper alloy samples with Ø250 mm working plate on automatic grinding and polishing machine Smoothneer-6.

TOP