400 099 7576

400 099 7576

Sample1

Sample2

Sample3

*The above pictures may not be forwarded without permission, otherwise legal liability will be pursued.

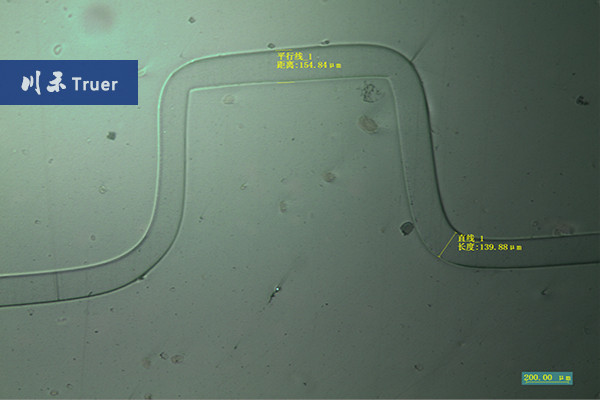

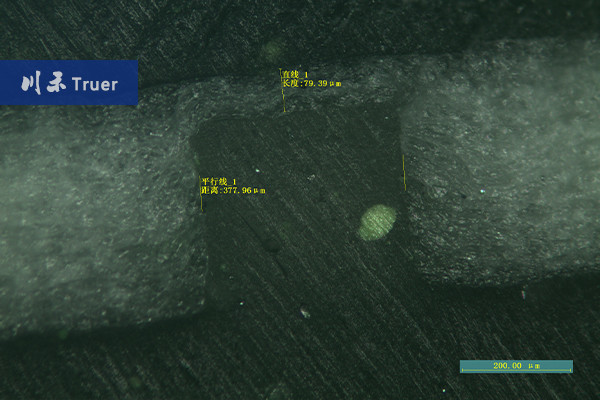

In view of the small size of chip components, the difficulty in grasping the specific observation surface, and the easy over-grinding, we used the quantitative grinding function of Smoothneer-6, which can accurately control the grinding removal amount of the sample from 50µm to 5000µm.

Smoothneer-6Metallographic Automatic Grinding and Polishing Machine Grinding Amount Control Interface

The following is the sample preparation method:

Mounting:

MC003 Vacuum-free Clear Cold Mounting Kit The sample after mounting

Grinding & Polishing:

|

The step of grinding & polishing |

Coarse Grinding |

Fine Grinding |

Diamond Coarse Polishing |

Diamond Fine Polishing |

Diamond Final Polishing |

|

|

1 |

Surface |

SiCsandpaper |

SiCsandpaper |

SiCsandpaper |

GD-PCC Acetate Satin |

GD-PCV Flannel (red short velvet) |

|

2 |

Abrasive Granularity |

800# |

1200# |

4000# |

3μm |

1μm |

|

3 |

Polishing/ Lubricant |

- |

- |

- |

DS001High performance polycrystalline diamond suspension |

DS001High performance polycrystalline diamond suspension |

|

4 |

Pressure |

25N |

25N |

25N |

20N |

15N |

|

5 |

Rotation Speed |

300 |

300 |

300 |

150 |

150 |

|

6 |

Time/min |

2 |

3 |

3 |

3 |

2 |

The above recommended parameters are taken from: Sample preparation method for Ø30 mm plastic with Ø250 mm working plate on automatic grinding and polishing machine Smoothneer-6.

TOP