2020-11-02

2020-11-02

Metallographic analysis is generally performed by microscopic observation of cross sections. Most of the samples after cutting are irregular in shape, which is inconvenient to clamp and grind, so most of the cut samples need to be inlaid into a standard size.

Hot mounting is to fill the resin particles into the mold, heat it to liquid state, tightly wrap the sample after pressurization, and demold it after curing. Hot mounting is mostly used for heat-resistant and pressure-resistant solid materials. Hot mounting is fast and simple, and the sample is dense and standard, so most metal materials are prepared by hot mounting.

The main indicators for evaluating hot mounting machines are as follows: :

1. Pressure supply capacity

Hot mounting resins soften after heating, but have poor permeability, and require external pressure to force resin penetration and densification. Especially for edge-preserving high-hardness resins with weak fluidity, pressures below 20MPa cannot achieve good densification, which means that for a sample with a diameter of 40mm, at least 250Kg of force is required. A hand-cranked, thousand-yuan machine is impossible, and pneumatic pressure is not enough. A hydraulic mounting machine with an independent hydraulic station must be used. Insufficient pressure will make the sample less dense, and all pores will bring potential defects to subsequent grinding and polishing. The following are some mounting defects caused by insufficient pressure.20MPa

2. Continuous pressure replenishment capability

After the external pressure reaches the set value, as the resin softens further and the volume shrinks, the pressure will decay rapidly. Therefore, a high-quality inlay machine must detect the pressure in the cylinder in real time and replenish the pressure to a reasonable range in time. The repeated start and stop of the hydraulic system not only affects the life of the equipment, but also generates noise. Therefore, a special pressure buffer system is needed to reduce the frequency of starting and stopping the equipment.

3. Mounting time

Mounting time has always been the weak point of hot mounting machines. Conventional domestic equipment usually takes about 30 minutes to mount. If the number of samples is large, it will take a long time. With the advancement of technology, some high-end equipment has greatly shortened the mounting time, basically controlling it to about 5 minutes. For example, the Pentration series of machines of Truer Company has greatly improved the mounting capacity if the left and right double barrels are in operation. The length of the mounting time is actually a comprehensive evaluation of the equipment's heating capacity, heat preservation capacity, pressurization capacity and cooling capacity. For example, the heating efficiency of the integrated heating is higher than that of the split assembly, and the cooling efficiency of the embedded type is higher than that of the outsourced type.entration

4. Parameter control

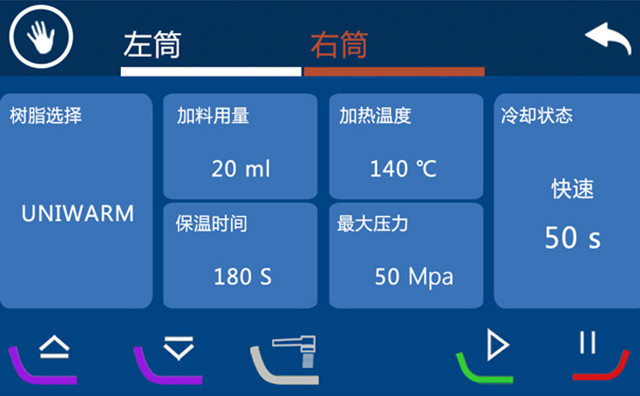

In addition to the basic requirements for equipment capabilities during hot mounting, key parameters including temperature, holding time, pressure, holding time, cooling speed, etc. must be quantitatively controlled and linked. High-end models must be equipped with a dedicated PLC or industrial computer system. In addition, the parameter settings required for various resins are different. Only by accurately controlling each parameter can the best mounting parameters be customized for different resins.PLC

From the above, it can be seen that a small machine has a great knowledge. To develop good equipment suitable for metallographic needs, it is necessary to abandon the low-end patchwork model, but to have a deep and detailed understanding of the sample preparation process with awe, which is also the current development direction of domestic metallographic equipment. All microscopic analyses are the accumulation and crystallization of countless details, and so is metallographic analysis.

Shanghai Truer Company has been deeply involved in the metallographic testing industry for decades, and has long practiced the concept of exquisite metallography. It is a leading metallographic solution provider in China. Truer takes international giants as benchmarks, faces difficulties, concentrates on research, overcomes key equipment and consumables that restrict the development of the industry, and creates a complete metallographic industry chain integrating equipment, consumables and sample preparation training; the company is equipped with cutting-edge metallographic laboratories and has a team of highly qualified experts. For more than ten years, it has provided metallographic analysis and sample preparation training services to thousands of customers, and provides customized metallographic laboratory solutions.

If you have any metallographic questions, you can get in touch with them to get the information you want.

TOP